Whether you’re an experienced professional or a beginner in welding, the quality of your welding table can significantly impact your project results. These work surfaces are built to withstand incredibly high temperatures and support high-power machinery.

Choosing the right table for your needs can be daunting, at times, especially if you don’t know what you’re looking for or what to shop for in the first place. Today, we’ll cover some of the most common welding table styles. We’ll also explain how to find one which one which works best for you.

For Light-Duty Welders

Those who only occasionally take on small, simple welding projects have a much easier time finding a suitable welding table. A thin sheet of aluminum or steel placed on some particle board or a wooden table will do the trick. Plywood may be cheaper, but it isn’t ideal, due to how curved large pieces are. Consider finding a foldable table to hang on your garage wall if you’re low on work area.

There are two primary drawbacks of this basic setup. One is the inability to clamp anything to the table without damaging it tightly. These types of “jury-rigged” tables can’t withstand much heat. Avoid rosebud welding if at all possible. Otherwise, this is an inexpensive table that will suit almost any light-duty welding job.

Stainless Steel Welders

If you’re primarily working with stainless steel welds, you’re going to need a more specific setup. Stainless steel doesn’t react well with other metals, so you must purchase a table made from the same material if you want to prevent cross-contamination. Welding on a carbon steel table will produce iron particles that will cause your end product to rust.

If you’re making food industry equipment, your guidelines are even more specific. The law requires welders making food industry equipment to weld on a stainless-steel table only. Anything else can result in fines or even lawsuits.

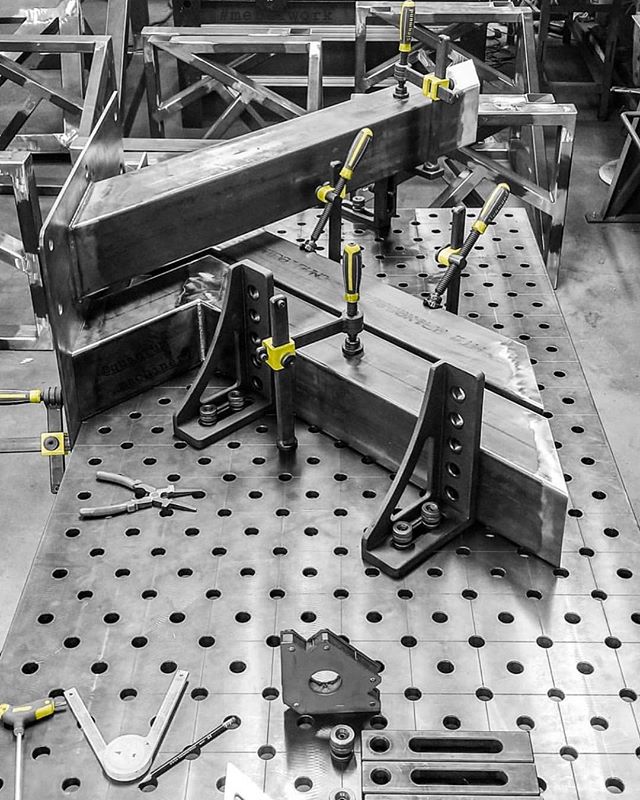

Buy a Brand Name Table

Brand name tables are hands-down your best option if you are wanting your dream welding table as opposed to some wooden pallets and bricks. Their prices vary widely, depending on what you want, ranging from a few thousand to tens of thousands. It’s a significant investment but is well worth the money!

We hope this guide has helped you decide on what type of welding table is right for you, but, if you’re still struggling to make a decision, reach out to us at Quantum Machinery Group. We’ll help you find a high-quality name brand table that won’t break the bank. We have a great selection of welding tables for welders of all experience levels.