PH50: Industrial Power Hammer (110 lbs. Per Stroke)

PH50: Industrial Power Hammer (110 lbs. Per Stroke)

Pre-Order Today: Lead Time is 8-10 weeks

READY TO PLACE AN ORDER, OR DO YOU HAVE ANY QUESTIONS?

CALL US AT (704)703-9400

PRICE: $14,999

Electrical Options:

220V / 1PH / 60Hz

120V / 1PH / 60Hz

The Quantum Nargesa Power Hammers PH50 Nargesa, are manufactured in welded and mechanized steel sheet. It is used in many blacksmith workshops to make all kinds of parts for the ornamental forging, which eases the job of moulding hot iron. Different tooling are used with it to inlay, mould, give shape, cut, pierce, rivetting and embossing, etc all kinds of metal.

All Nargesa products are manufactured in our facilities in Spain. Hydraulic and electrical components are completely standard and from the the best leading European trademarks which have technical support all around the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

The PH50 Features and Specifications:

Nominal dropping weight: 50 kg / 110 lb

Strokes per minute: 240

Ram range: 180 mm / 7”

Operating range: 220 mm / 9”

Maximum round working capacity: 70 mm / 2.75”

Maximum square working capacity: 60x60 mm / 2.36”

Engine power: 2.2 kW / 3 HP

Electrical voltage: 230/400 V three-phase 50/60 Hz

Single-phase: 220 V voltage OPTIONAL

Intensity: 9/5 A

Weight: 2186 lbs.

Dimensions: 31"x51"x70" (808x1289x1768mm)

Built-in compressor.

Maximum drop precision, controlled via a next-generation valve.

Welded and die-cut steel frame.

Automatic greasing system.

Lapped cylinders designed with low-friction technology.

Intake and exhaust mufflers.

Automatic inner ventilation.

Inner tray to collect greasing oil.

Near-zero maintenance.

Double mechanical stop protection.

Height and orientation adjustable protection on the front.

Drive system pedal protection.

Electric engine protection.

Emergency stop.

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Built-in Compressor

The PH50 power hammer has a built-in compressor. This means, unlike with other brands, no external compressor is needed. A 50 kg or 110 lb power hammer without a built-in compressor would need a 5 HP external compressor. This leads to extra costs on electricity since it is necessary.

Simple Installation

A special foundation that insulates the machines from the ground is needed to install 90% of all power hammers currently on the market. This requires formwork, which can be costly, to guarantee proper operation and prevent vibrations from disturbing neighbors. On the other hand, only 4 holes are needed in a concrete floor to insert the 4 chemical bolts that come with the machine when installing the PH50 power hammer.

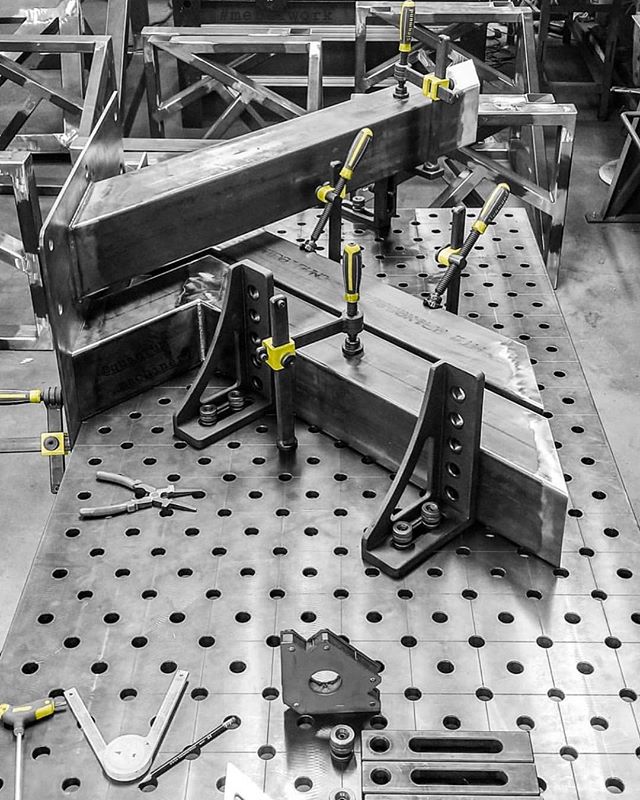

Welded Steel Frame

The machine frame is not casted; it’s made of welded and die-cut steel. This reduces the possibility of cracking, as occurs with cast power hammers. Plus, the impact is much more efficient since it’s a single piece. Likewise, the insulation at the base of the machine minimizes the transfer of vibrations to the ground.

THE NARGESA PH50 FEATURES

Maximum Controlled Drop Precision

The all-new valve system enables absolute control. One of the main concerns of blacksmiths worldwide was how to control the drop. After conducting tests for 3 years with different valves, together we achieved maximum precision The result is UNBEATABLE EASE OF USE. After just a few hours of practice, it can be perfectly dominated unlike other power hammers, which require years of experience.

Automatic Lubrication System

Another highly important aspect of the machine is the lubrication system. The lubrication system on the PH50 power hammer features a completely transparent tank next to the power switch to monitor the level of oil in the container without having to use uncomfortable inspection peepholes.

Intake & Exhaust Mufflers

The noise of the impact of the power hammer when in operation is quite difficult to minimize and is usually linked to the location inside the building. We’ve minimized the noise the machine makes when at rest. Two mufflers, on the intake and exhaust, reduce the noise.

Lapped Cylinders Design

The friction between the sleeve and piston is normally mechanical and through steel rings. This causes a risk of seizing up over time. The cylinders on the PH50 power hammer never come into physical contact with the piston, thus enhancing the efficiency and eliminating any mechanical wear.

Double Mechanical Stop Protection

The mechanical stop safety mechanism makes it impossible for the hammer ram to accidentally activate. The piston on the front and pedal become completely mechanically blocked in an ideal position to easily and safely change the molds. Unlike most power hammers, there’s no need with the PH50 to insert a wooden wedge between the anvil and the ram to switch tools.

Collecting & Filtering

All pneumatic drop hammers discharge little drops of diluted oil into the air and this contaminating mix then enters the environment. The Nargesa PH50 drop hammer has a tank that collects this mix and separates the two components. On the one hand, it discharges the air to the outside and, on the other, it recovers the excess oil in a container inside that can be accessed through the back. This prevents the pollution of the work area. NOTE: This grease must be recycled pursuant to the regulations in effect in each country. Looking after the planet is everyone’s responsibility.

The PH50 STANDARD TOOLING:

Standard Flat Mold for the PH50 Power Hammer (REF: 140-14-04-00001)

All our Power-hammers are equipped with an upper standard flat tooling and lower one.

This tooling is the most versatile one and it’s bond to the operative's skillfulness. Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Standard Tool: Nº of pieces: 2

Dimensions: 4.7"x3" (120x78mm)

Support Braces/ Adaptors for the PH50 Power Hammer (REF: 140-14-04-00002)

We supply two sets of Support braces along with the power hammer PH50. These adaptors enable us to weld or fasten bolts to several elements, such as round and square solid bars, flat bars, rods, etc… to manufacture our tools. Tools made of Steel F111.

Standard Tool: Nº of pieces: 4

Dimensions: 4.7"x3.5" (120x89mm)

The PH50 OPTIONAL TOOLING: