C3006 10 FOOT HYDRAULIC SHEAR

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $68,853

Electrical Options:

- 220V / 3PH / 60Hz

- 480V / 3PH / 60Hz

The last generation of QUANTUM NARGESA CNC Vertical cut shears are made of stabilized, welded steel that allows to take on big jobs without deformation.

Cutting Length: 119” / 3,030mm.

Max. Thickness in Mild Steel: 0.230” / 6mm.

Max. Thickness in Stainless Steel: 0.150” / 4mm.

ADVANTAGES OF VERTICAL CUT INSTEAD OF SWING CUT:

Energetic saving: Resistance of material in vertical cut is much lower, which becomes a considerable energetic saving.

Cutting quality: Clean, perfect and accurate cut.

Life of the blades: The blades wear is almost nule. The life of the blades is 4 times higher than other shearing systems.

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $68,853

Electrical Options:

- 220V / 3PH / 60Hz

- 480V / 3PH / 60Hz

The last generation of QUANTUM NARGESA CNC Vertical cut shears are made of stabilized, welded steel that allows to take on big jobs without deformation.

Cutting Length: 119” / 3,030mm.

Max. Thickness in Mild Steel: 0.230” / 6mm.

Max. Thickness in Stainless Steel: 0.150” / 4mm.

ADVANTAGES OF VERTICAL CUT INSTEAD OF SWING CUT:

Energetic saving: Resistance of material in vertical cut is much lower, which becomes a considerable energetic saving.

Cutting quality: Clean, perfect and accurate cut.

Life of the blades: The blades wear is almost nule. The life of the blades is 4 times higher than other shearing systems.

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $68,853

Electrical Options:

- 220V / 3PH / 60Hz

- 480V / 3PH / 60Hz

The last generation of QUANTUM NARGESA CNC Vertical cut shears are made of stabilized, welded steel that allows to take on big jobs without deformation.

Cutting Length: 119” / 3,030mm.

Max. Thickness in Mild Steel: 0.230” / 6mm.

Max. Thickness in Stainless Steel: 0.150” / 4mm.

ADVANTAGES OF VERTICAL CUT INSTEAD OF SWING CUT:

Energetic saving: Resistance of material in vertical cut is much lower, which becomes a considerable energetic saving.

Cutting quality: Clean, perfect and accurate cut.

Life of the blades: The blades wear is almost nule. The life of the blades is 4 times higher than other shearing systems.

TECHNICAL FEATURES

Cutting length: 3030mm.

Cutting capacity: 6mm in steel (450N/mm2)andy 4mm in S.S.(700N/mm2)

CNC back gauge.

Digital display.

Gauge displacemnt: 700mm.

Accuracy and repeatability of positioning from +/- 0,1mm.

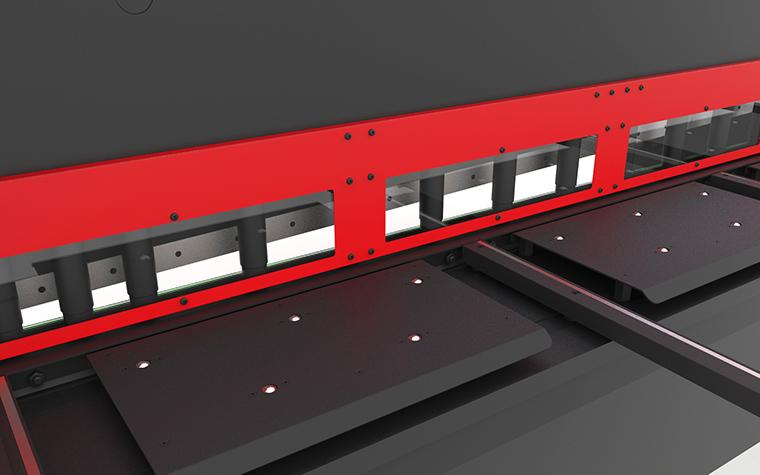

4-edged lower and upper blades Suitable for stainless steel.

Goose neck for cuts with bigger length: 173mm.

Cutting area lit up by leds.

Thin marking zone for manual cutting.

Strokes per minute: 12 Strokes. (All length)

Independent hydraulic rammers: 15 units.

Millimeter squaring arm, 1000mm length.

Two 1000mm-millimetered stand arms.

Fix cut inclination: 1,75º

Driving with safety pedal and emergency stop.

Back overture with safety optoelectronic devices.

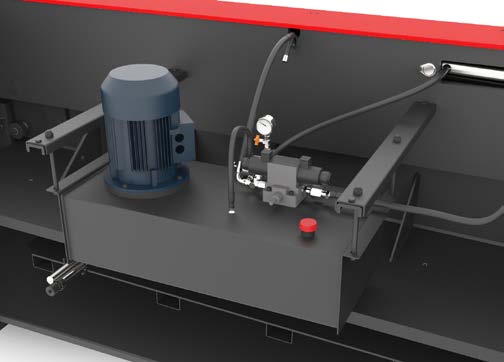

Motor power: 9,2 KW/ 12 HP

3-Phased tension: 400 V.

Hydraulic Pump: 22 liters.

Container capacity: 96 liters.

Precision rear gauge

Rear gauge fixed to the structure.

Accuracy and repeatability of positioning from +/- 0,1mm.

Low maintenance thanks to the use of low friction elements.

ESA S625 compact CNC

The control interface is very intuitive and easy to use.

Internal database of materials.

Configuration of the piece length by the CNC.

Enhanced hydraulic group

Automatic regulation of the cutting pressure depending on the need for cutting power.

Automatic regulation of the pressure of the sheet fastenings.

COMPACT CNC CONTROL ESA S62

The operator only has to enter the type of material, thickness, distance from the gauge and the CNC will automatically arrange all components to obtain an optimal result.

Equipped with a 7 "touch screen which makes all operations on the machine simpler and more intuitive.

You can manage up to 3 axes and 16 + 12 I / O with an integrated PLC.

Storage of thousands of parts programs.

7 "800x480 color touch screen resolution

128 MB silicon disk.

2 analog inputs, 12-bit resolution.

16 digital inputs (24Vdc).

16 digital outputs (24V DC, 0.7 A max.) Protected against overloads and short circuits.

1 RS232 serial port

1 CAN port with 9 contacts Sub D F connector.

24Vdc power supply.

1 USB input.

1 Ethernet port that allows connection remotely.

REAR STOP

The back gauge, fixed to the machine’s beam or ram, accompanies the material during the cutting process. The back gauge places quickly and accurately on the required position (± 0.1 mm).

The addition of the CNC eliminates the continuous regulations and allows maintenance to be reduced to a minimum level.

RAMP OF MATERIAL EXTRACTION

Ramp of material extraction This metallic ramp located in the lower part of the cutting zone allows the material to slide down to the extraction area

HYDRAULIC CURCUIT

Fully optimized with high quality and reliability components.

It manages the pressure of the pressing cylinders with respect to the shearing force and the cutting length depending on the piece to be cut.

LASER LIGHTING ON THE CUTTING LINE

Sometimes the geometry of the sheet to be cut and the characteristics of the cut require the operator to visualize a clear cut line. Laser illumination fulfills this function, making this line visible.

FRONT SUPPORTS

The front supports are blocks fixed and machined to the monoblock of the bench. They are equipped with millimeter scales and the initial support has got a lateral gauge with a cutting start square.

TABLE

The bench is manufactured in a mechanized single-block and it is a part of the structure. It was dimensioned and optimized by simulation of finite element analysis. Some sliding spheres fixed to the table decrease the friction of the material and contribute to its sliding, facilitating the load to the operator.

POLYCARBONATE FRONT PROTECTION

These protection screens let the operator have the complete vision of the cutting area and help to place the sheets through the laser cutting line.

HYDRAULIC HOLDERS

The regulation of the pressure of the holders is carried out automatically according to the cutting force. In this way, we prevent from having to press excessively and from damage particularly delicate sheets.

DIMENSIONS OF THE MACHINE HYDRAULIC SHEARS C2006 CNC

Dimensions of the machin: 3865x2457x1816 mm.

Weight: 7500 Kg.

Tariff Item Cod: 84623991

Other Features:

The machine is delivered completely asssembled.

USES OF THE MACHINE: HYDRAULIC SHEAR C3006 CNC

Last generation CNC vertical cut Shears C3006, allows cutting any kind of metal in a clean and exact way. The shearing is much more accurate, what turns out in a reduced energetic consumption and minimum wear of blades.