PP200 HORIZONTAL PRESS BRAKE

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $17,700

Electrical Options:

- 220V / 3PH / 60Hz

- 480V / 3PH / 60Hz

- 220V / 1PH / 60Hz

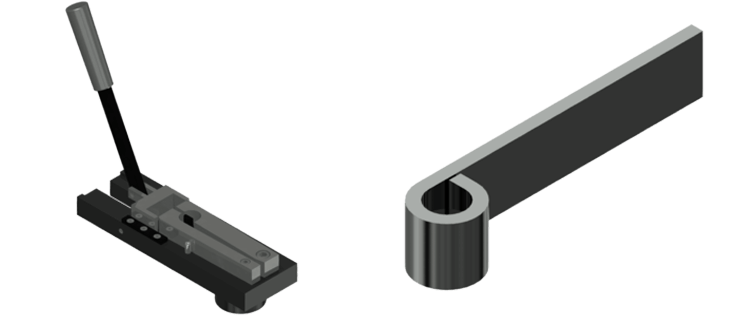

The versatility of the 20 Tons Horizontal Press Brake QUANTUM NARGESA PP200 allows us to bend, fold, cut and shape in cold, stretch and reduce, inlay, notch and assemble... Horizontal Bending Press Brake PP200 has been manufactured in a 60mm thick welded steel monoblock, stabilized and mechanized. Its robustness, versatility and easy handling are just three of the best features our hydraulic horizontal bending machine has.

FEATURED CHARACTERISTICS:

Easy handling: The machine is sent completely assembled, it is only necessary to connect it to the required power supply and start performing.

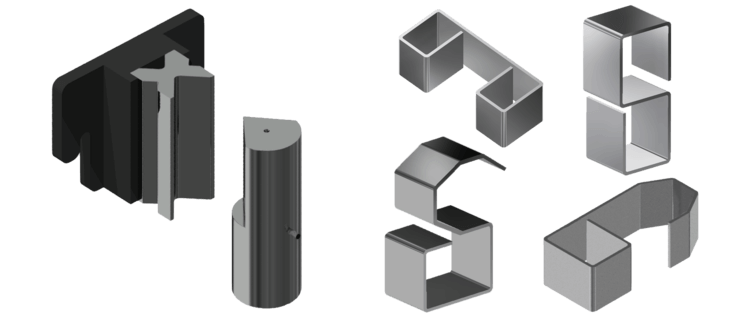

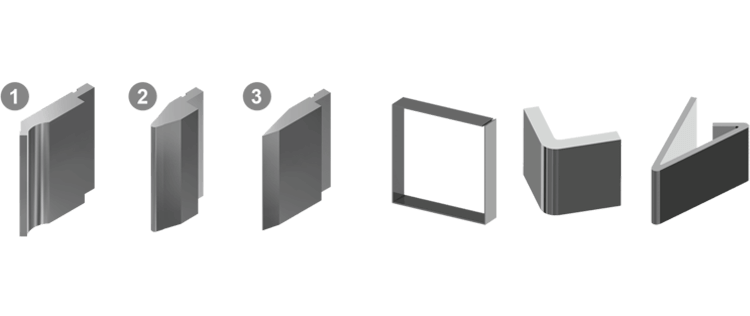

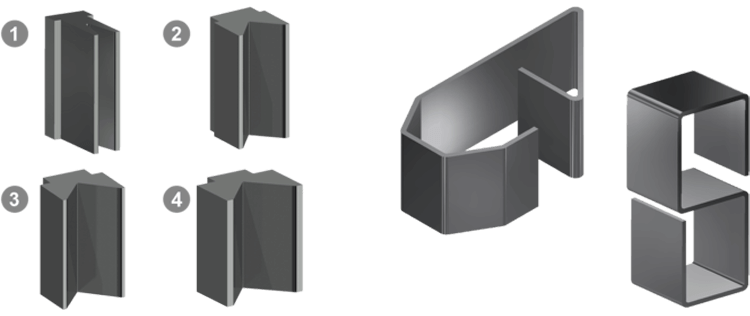

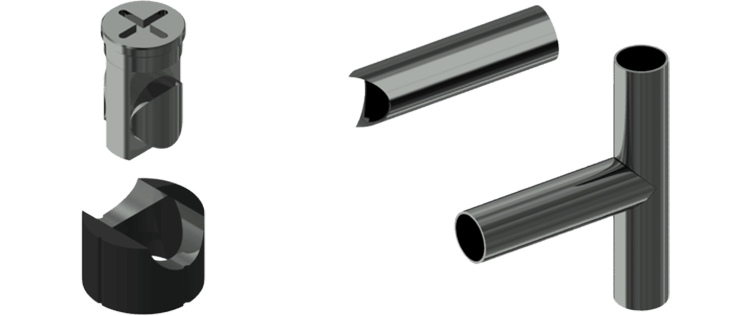

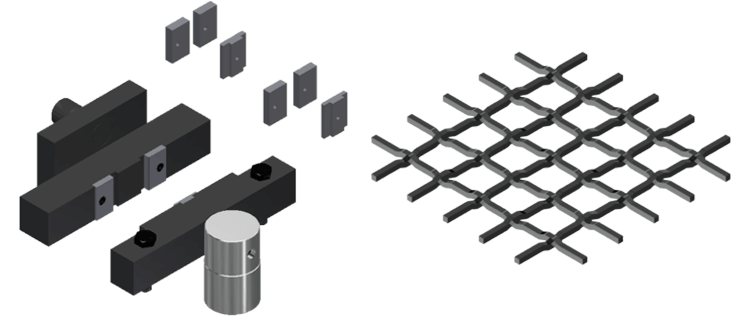

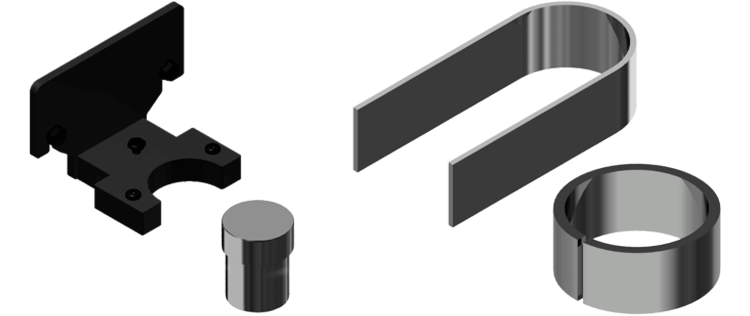

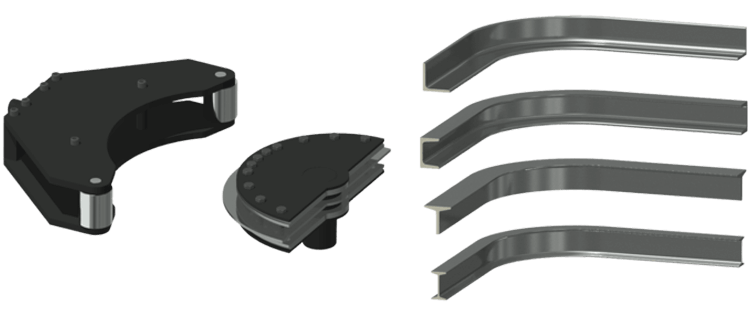

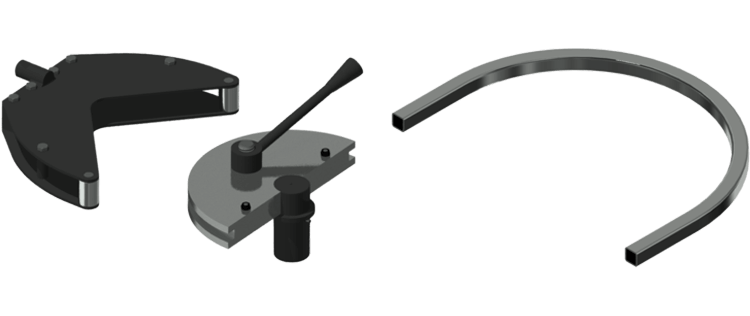

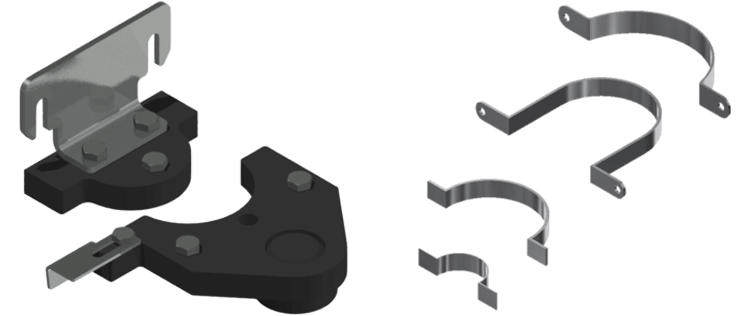

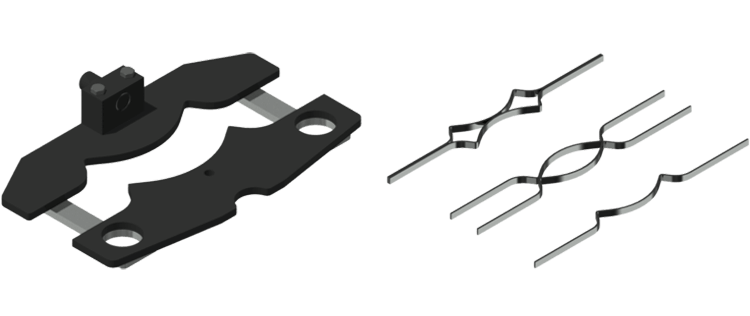

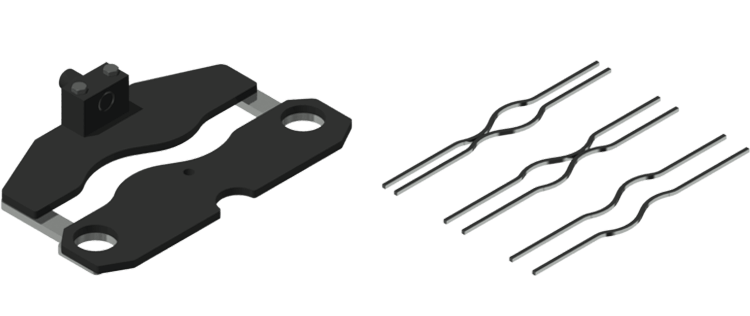

Versatility: Nargesa PP200 has a catalog with a great deal of optional tooling. (See optional tooling and sample video below)

Easy fabrication of tooling: The customer himself or any toolmaker can manufacture dies and punches.

Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes.

Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations that are impossible to be carried out on a conventional press brake.

Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times.

STANDARD EQUIPMENT PROVIDED WITH THE MACHINE: Horizontal press brake PP200 includes the complete 4V’s folding die.

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $17,700

Electrical Options:

- 220V / 3PH / 60Hz

- 480V / 3PH / 60Hz

- 220V / 1PH / 60Hz

The versatility of the 20 Tons Horizontal Press Brake QUANTUM NARGESA PP200 allows us to bend, fold, cut and shape in cold, stretch and reduce, inlay, notch and assemble... Horizontal Bending Press Brake PP200 has been manufactured in a 60mm thick welded steel monoblock, stabilized and mechanized. Its robustness, versatility and easy handling are just three of the best features our hydraulic horizontal bending machine has.

FEATURED CHARACTERISTICS:

Easy handling: The machine is sent completely assembled, it is only necessary to connect it to the required power supply and start performing.

Versatility: Nargesa PP200 has a catalog with a great deal of optional tooling. (See optional tooling and sample video below)

Easy fabrication of tooling: The customer himself or any toolmaker can manufacture dies and punches.

Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes.

Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations that are impossible to be carried out on a conventional press brake.

Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times.

STANDARD EQUIPMENT PROVIDED WITH THE MACHINE: Horizontal press brake PP200 includes the complete 4V’s folding die.

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $17,700

Electrical Options:

- 220V / 3PH / 60Hz

- 480V / 3PH / 60Hz

- 220V / 1PH / 60Hz

The versatility of the 20 Tons Horizontal Press Brake QUANTUM NARGESA PP200 allows us to bend, fold, cut and shape in cold, stretch and reduce, inlay, notch and assemble... Horizontal Bending Press Brake PP200 has been manufactured in a 60mm thick welded steel monoblock, stabilized and mechanized. Its robustness, versatility and easy handling are just three of the best features our hydraulic horizontal bending machine has.

FEATURED CHARACTERISTICS:

Easy handling: The machine is sent completely assembled, it is only necessary to connect it to the required power supply and start performing.

Versatility: Nargesa PP200 has a catalog with a great deal of optional tooling. (See optional tooling and sample video below)

Easy fabrication of tooling: The customer himself or any toolmaker can manufacture dies and punches.

Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes.

Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations that are impossible to be carried out on a conventional press brake.

Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times.

STANDARD EQUIPMENT PROVIDED WITH THE MACHINE: Horizontal press brake PP200 includes the complete 4V’s folding die.

DOWNLOADS

AVAILABLE ACCESSORY OPTIONS:

INFO HORIZONTAL PRESS BRAKE PP200

Before you buy a Horizontal Bending Press Brake you should know about the difficulties that exist when fitting the non-standard folding, bending or forming special parts dies. Sometimes there are facts that make it for customers hard to invest in a complicated tooling when customized pieces must be made, tight lead time, the small number of parts to be manufactured or lack of budgeting. The advantage of the Horizontal Bending Press PP200 is to have a really simple head drive so that all our customers can adapt any die manufactured by themselves. To add more options when fastening tools, the workbench has a series of clamping holes distributed throughout the area to ease up the fixing.

If you need a special die, Prada Nargesa offers a technical support to all our customers who wish to make their own tools. Moreover, we have an extra service for designing and manufacturing exclusive tooling on request, for each of the machines we manufacture.

DIMENSIONS OF THE MACHINE HORIZONTAL PRESS BRAKE PP200

Dimensions of the machine: 958x1200x1126 mm.

Weigh: 625 Kg.

Tariff Item Code: 84624990

Other features:

Palletized base to move it easily to the working site or storage.

The machine is delivered completely mounted.

USES OF THE MACHINE: HORIZONTAL PRESS BRAKE PP200

There are multiple uses for the Horizontal Bending Press PP200 NARGESA. The large number of tools that complement it allow several operations in different materials and in different types of profiles. Bending and folding flat bars with horizontal press will enable the manufacturing of completely closed pieces that would be difficult to obtain by using other machines. Bending and curving tubes to different degrees to make tables, chairs, pool ladders, car protections, parking lot protections, fitness machines etc ... Straightening and bending large profiles to conform bus chassis, prototypes with complicated curves and bends, straightening faulty profiles ... Cutting flat bars or metal sheets a lot faster than any other saw or cutting machine. Punching, boring, drilling or punching plates to make perforations on fences, doors, windows and other parts. Cutting and shaping are other features of this versatile forming press for manufacturing flanges and clamps for fastening pipes. Flaring tube or pipe for assembly and subsequent welding to produce exhaust pipes, water pump distributors, metal furniture, railings tube... Widening and reducing the pipe ends permit joining different pipes to make berths, chairs, irrigation systems, tents, greenhouses etc... Folding and bending solid rods will enable the user to manufacture all kinds hooks, chain links and also form balusters out of square or round bars, tubes for the manufacturing of parts for cold forging, railings, fences, gates, doors, railings... Making hinges is another widely used application in this type of hydraulic press. As you can see, the uses of Hydraulic Horizontal Bending Press Nargesa PP200 are really limitless.