The MC150B Roll Bender (Bend up to 2" O.D. Round Tube)

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $6,999

Electrical Options:

220V / 3PH / 60Hz

480V / 3PH / 60Hz

220V / 1PH / 60Hz

The MC150B Quantum Nargesa Roll Bender / Section and Pipe Bending Machine was designed to drastically minimize the manufacturing cost and provide maximum performance when bending pipes and profiles. It has been manufactured for different profiles such as flat bar or bar section, T-profile, rolling U-profile, bending angle, bending solid rod, both square and round types, spiral tube or even to perform square, rectangular or round pipe in different materials: iron, carbon steel, stainless steel, brass, copper, aluminum. The purpose of these bending operations varies from making greenhouses, tables, chairs, car guards, doors, windows, railings, fences and countless more metal products.

All Nargesa products are manufactured in our facilities in Spain. Hydraulic and electrical components are completely standard and from the the best leading European trademarks which have technical support all around the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $6,999

Electrical Options:

220V / 3PH / 60Hz

480V / 3PH / 60Hz

220V / 1PH / 60Hz

The MC150B Quantum Nargesa Roll Bender / Section and Pipe Bending Machine was designed to drastically minimize the manufacturing cost and provide maximum performance when bending pipes and profiles. It has been manufactured for different profiles such as flat bar or bar section, T-profile, rolling U-profile, bending angle, bending solid rod, both square and round types, spiral tube or even to perform square, rectangular or round pipe in different materials: iron, carbon steel, stainless steel, brass, copper, aluminum. The purpose of these bending operations varies from making greenhouses, tables, chairs, car guards, doors, windows, railings, fences and countless more metal products.

All Nargesa products are manufactured in our facilities in Spain. Hydraulic and electrical components are completely standard and from the the best leading European trademarks which have technical support all around the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Ready to place an order, or do you have any questions?

Call us at (704) 703-9400

Price: $6,999

Electrical Options:

220V / 3PH / 60Hz

480V / 3PH / 60Hz

220V / 1PH / 60Hz

The MC150B Quantum Nargesa Roll Bender / Section and Pipe Bending Machine was designed to drastically minimize the manufacturing cost and provide maximum performance when bending pipes and profiles. It has been manufactured for different profiles such as flat bar or bar section, T-profile, rolling U-profile, bending angle, bending solid rod, both square and round types, spiral tube or even to perform square, rectangular or round pipe in different materials: iron, carbon steel, stainless steel, brass, copper, aluminum. The purpose of these bending operations varies from making greenhouses, tables, chairs, car guards, doors, windows, railings, fences and countless more metal products.

All Nargesa products are manufactured in our facilities in Spain. Hydraulic and electrical components are completely standard and from the the best leading European trademarks which have technical support all around the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

The MC150B Bending Capacities:

Solid Round: 1" with a Minimum Radius of 8" Inches

Solid Square: 1" x 1" with a Minimum Radius of 8" Inches

Flat Bar (Hard Way): 2" x 0.315" with a Minimum Radius of 12" Inches

C-Channel (Easy Way): 2" with a Minimum Radius of 8" Inches

C-Channel (Hard Way): 2" with a Minimum Radius of 10" Inches

Round Tube: 2" x .120" with a Minimum Radius of 24" Inches

Square Tube: 1.5" x 1.5" x .120" with a Minimum Radius of 14" Inches

Flat Bar (Easy Way): 2.25" x 0.75" with a Minimum Radius of 8" Inches

Angle (Leg-Out): 1.5" with a Minimum Radius of 20" Inches

T-Channel (Easy Way): 1.5" x 1.5" with a Minimum Radius of 8" Inches

*Please Note - Minimum Radii shown may require multi-pass. The sizes shown above are the maximum capacity with minimum radii. Round Profiles and Special Profiles shown above will require dedicated tooling. When bending smaller sections, the machine will be able to bend very small radii.*

The MC150B Features and Specifications:

Rollers Speed: 6 RPM

Diameter of Axes: 1.5"

Useful Axes Length: 2.9"

Motor Power: 0.75 KW / 1 HP

Dimensions: 37"L x 27"W x 45"H

Base cupboard for rollers and accessories.

Center Distance between Lower Axes: 9"

Millimeter scale for bending in the upper shaft.

Secure transmission by using flat hardened pinions.

Maximum Capacity for Bending Round Tube: 2 inches or 50 mm

Two working positions, horizontal and vertical in the same workbench.

Two drive rollers. The two lower rollers are motorized and knurled for better grip.

Manufacturer's Warranty: 3 Years on All Parts (Fulfilled by Quantum Machinery Group.)

Lower bench palletized to easily transport the machine to the workplace or store it in case of lacking space.

Correction rollers on the sides to control the bending deformation when making spirals and spiral staircases.

Bending regulation by the upper shaft, which allows to curve tube and profile dimensions and profiles of large diameter without deformation.

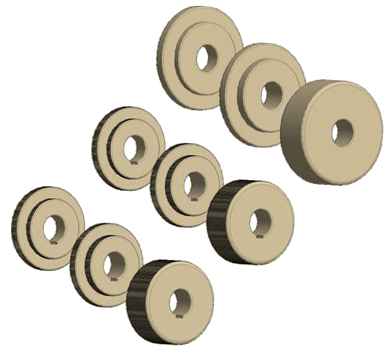

Standard Tooling Configuration:

The MC-150B is equipped with 9 standard pieces, by means of which the user can work all kinds of profiles. Square, Rectangular Tube, Square Bars, C-Channel, T-Channel, Angle, Flat Bar, and Edged Flat Bar.

Adjustable rollers, by washers with the size of profile which allows us to make bending to different profile sizes.

When the user has to bend any kind of profile at radius wider than 2 m or if there are height problems in the facilities, it is really uncomfortable to work vertically. It will be enough with just bending the machine down so the bending operation is made horizontally with the help of a support or stands where we place the piece in order to obtain an acceptable job. For instance, when you need to bend arches for a greenhouse.