Image 1 of 13

Image 1 of 13

Image 2 of 13

Image 2 of 13

Image 3 of 13

Image 3 of 13

Image 4 of 13

Image 4 of 13

Image 5 of 13

Image 5 of 13

Image 6 of 13

Image 6 of 13

Image 7 of 13

Image 7 of 13

Image 8 of 13

Image 8 of 13

Image 9 of 13

Image 9 of 13

Image 10 of 13

Image 10 of 13

Image 11 of 13

Image 11 of 13

Image 12 of 13

Image 12 of 13

Image 13 of 13

Image 13 of 13

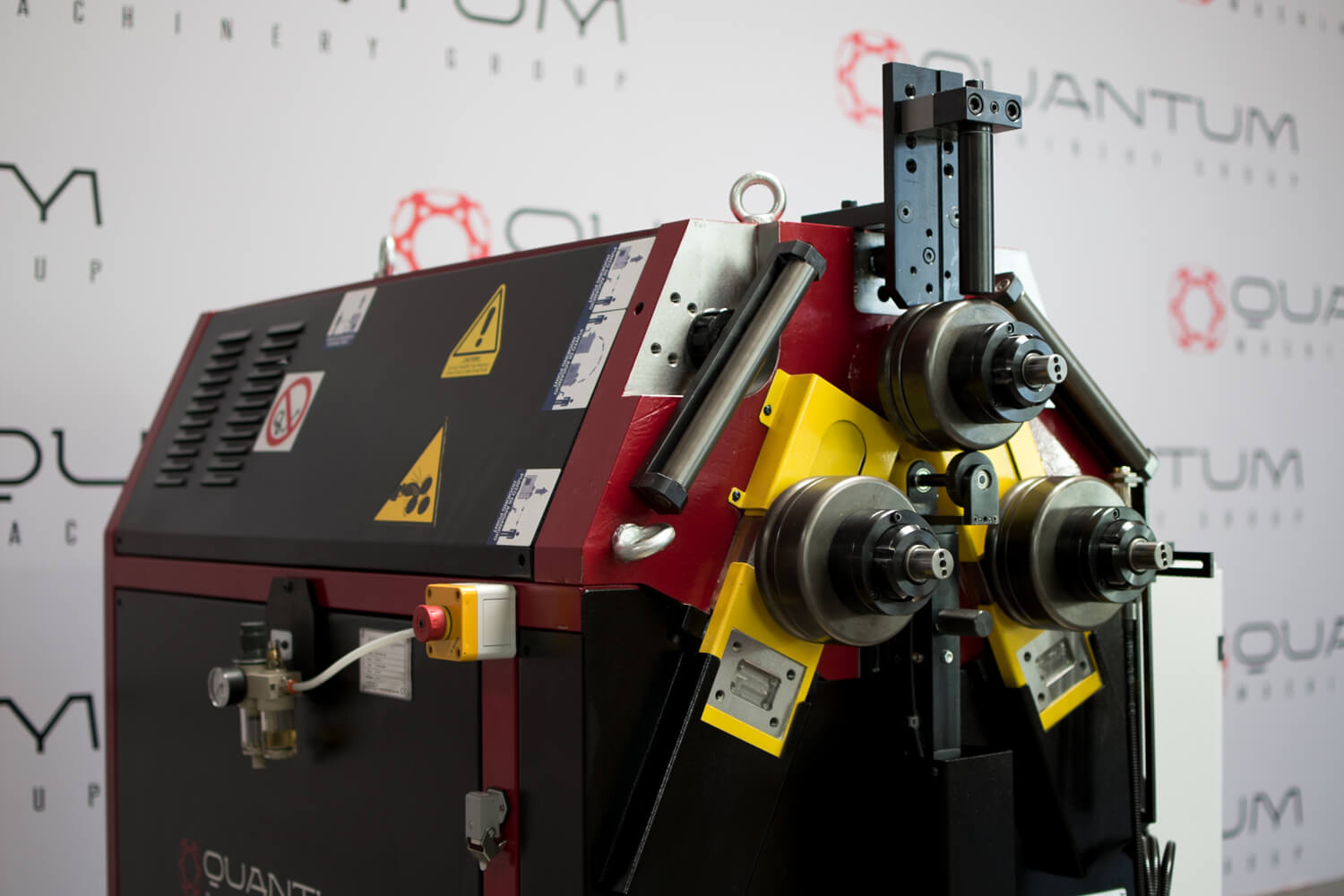

The D60 CNC PRO Roll Bender (Bend up to 3.5" O.D. Round Tube)

Ready to place an order, or do you have any questions? Call us at (704)703-9400

THE QUANTUM D60 CNC PRO IS A PYRAMID-STYLE, HYDRAULIC ROLL BENDER, IDEAL FOR BENDING A WIDE VARIETY OF APPLICATIONS.

STANDARD FEATURES:

3 Driving Rolls

7.7 R.P.M.

60mm Shaft Diameters

High-Quality, Italian Build

Equipped with the Quantum CNC PRO (Touchscreen CNC Control)

LED Display for Digital Readout of Top Roll Position

Includes Interchangeable Universal Tooling

6.3" Standard Shaft Working Length

Weighs Approximately 2,300 lbs.

Machine Dimensions: 45" x 59" x 67"

Ready to place an order, or do you have any questions? Call us at (704)703-9400

THE QUANTUM D60 CNC PRO IS A PYRAMID-STYLE, HYDRAULIC ROLL BENDER, IDEAL FOR BENDING A WIDE VARIETY OF APPLICATIONS.

STANDARD FEATURES:

3 Driving Rolls

7.7 R.P.M.

60mm Shaft Diameters

High-Quality, Italian Build

Equipped with the Quantum CNC PRO (Touchscreen CNC Control)

LED Display for Digital Readout of Top Roll Position

Includes Interchangeable Universal Tooling

6.3" Standard Shaft Working Length

Weighs Approximately 2,300 lbs.

Machine Dimensions: 45" x 59" x 67"

Ready to place an order, or do you have any questions? Call us at (704)703-9400

THE QUANTUM D60 CNC PRO IS A PYRAMID-STYLE, HYDRAULIC ROLL BENDER, IDEAL FOR BENDING A WIDE VARIETY OF APPLICATIONS.

STANDARD FEATURES:

3 Driving Rolls

7.7 R.P.M.

60mm Shaft Diameters

High-Quality, Italian Build

Equipped with the Quantum CNC PRO (Touchscreen CNC Control)

LED Display for Digital Readout of Top Roll Position

Includes Interchangeable Universal Tooling

6.3" Standard Shaft Working Length

Weighs Approximately 2,300 lbs.

Machine Dimensions: 45" x 59" x 67"

State-of-the-art CNC (Pyramid Style), three gear driven Roll Bender. Lower roll centers can be positioned in four different positions (280mm, 330mm, 380mm or 430mm center distances). All three shafts are hardened, ground high strength steel, which are mounted on taper roller bearings for high radial or axial loads. The top roll is equipped with a friction mechanical device for rim speed compensation. The frame is made out of rugged steel. The D60 comes with a self-braking motor and is in conformity with “CE” Regulations (89/392 CE). Electromagnetic compatibility, (89/336) Low tension (73/23,93/68).

The Quantum D60 CNC PRO Roll Bender Standard Capacities:

(PLEASE NOTE – The minimum radii shown may require Multi-Pass. PLEASE ALSO NOTE - The sizes shown are the of the maximum capacity with the minimum radii; when bending smaller profiles, the machine will be able to bend smaller radii.)

Round Tube: 3.5" x .10” with a 45" Minimum Radius

Solid Round: 2.5” with a 21" Minimum Radius

Square Tube: 3.15” x 3.15" x .140" with a 45" Minimum Radius

Angle (Leg-Out): 3.15" x 3.15" x .315" with a 29" Minimum Radius

Flat Bar (Easy Way): 5.25" x 1.4” with a 25" Minimum Radius

T-Channel (Easy Way): 2.8" x 2.8” x .35" with a 21" Minimum Radius

Pipe: 2.50" Sch. 40 Pipe (2.875" O.D.) with a 27" Minimum Radius

Rectangular Tube (Easy Way): 4.25" x 2.125” x .14" with a 45" Minimum Radius

Solid Square: 2.125" x 2.125” with a 21" Minimum Radius

Angle (Leg-In): 3.15" x 3.15" x .315" with a 37" Minimum Radius

Flat Bar (Hard Way): 3.5" x .70” with a 37" Minimum Radius

T-Channel (Hard Way): 2.8" x 2.8” x .35" with a 21" Minimum Radius

THE CNC PRO: CNC TOUCHSCREEN CONTROL

Computerized Numerical Interpolated Control

- Joints and Bending Radii Predetermination

- Anti-Skid "No-Slip" System

- Autocad DXF File Import

- Roll Diameter Automatic Survey

The CNC PRO is the new, revolutionary computerized numerical control system with interpolated axis. Now with the latest in user interface and graphics and can manage up to 16 moving axis simultaneously.

The interpolation system automatically adapts, without any operator intervention, each axis speed, allowing the machine to easily obtain the desired shape with the previously established links, which depend on the bending profile. In this way, programming becomes extremely easier and more rapid.

The shapes that are directly designed on the CNC PRO Control Touchscreen correspond exactly to what appears on the Simulation Screen and to the shape physically obtained from the machine. This characteristic makes the programming easier and allows the execution of perfectly symmetric shapes.

CNC PRO Features:

Some of the main features of the CNC PRO control that easily set us apart from the competition:

Symmetrical parts production

Machine automatically inputs speeds on X and Y movements, by having this feature you will not rely on the operator. With other units out there you rely on the operator for this critical area, which can result in loss of parts/scrap.

Downloading .dxf files. You can download .dxf files to a USB key and quickly input those files onto the machine control.

Windows based operator system

Our ARC meter is used to measure

radii, direct input reading in inches or millimetersGraphical design – shows you the bending result using a graph

Multiple axis interpolation

Anti-slip with automatic material feed tracking system – unlike traditional CNC systems out in the market today this system knows if there material slips during the bending process. If slippage occurs the machine automatically slows down so you do not scrap material

Capable of changing radius during automatic cycle

Profile – spring back

Automatic calibration of roll diameters

Variable speed controls

Parts counter

Predetermined icons for quick input programming

Machine can be used in the vertical or horizontal position

The trial and error method of adjusting the speeds to get the desired transition lengths is No Longer Necessary.

» A length is entered and the control automatically adjust speeds to regulate the transitions length in order to get a symmetrical bent piece.

» Symmetrical Bent Parts without the Guess Work.

» Anti-Slip Automatic Material Feed Tracking System The material is constantly being monitored as it is rolled.

Speeds and feeds are automatically adjusted by the control eliminating possible material slippage which normally occurs when rolling tight radii.

PROGRAMMED SHAPE VISUALIZATION:

Gives the possibility to visualize, in three dimension the programmed shape.

SELF PROGRAMMING:

Allows you to automatically create the program using pre-determined shapes. The programming of shapes like the three-centered arch is extremely facilitated into the system, by entering some of the dimensions. The CNC PRO automatically draws & calculates the bending program.

DESCRIPTION:

The CNC PRO is the new computerized numerical interpolated control system. The system relies on the latest industrial computer to manage and store programs and on a control unit to manage the axis and input/output. The CNC PRO can manage simultaneously each axis.

» The interpolation system automatically adapts each axis speed without the operator intervening so to easily obtain the desired shape with the previously established links. By using this system the operator doesn’t have to plan each axis speed in order to determine the link amount of the curves; he only has to plan the axis length in millimeters or leave the control to automatically predetermine the links from the shape to be obtained. Programming becomes easier and faster and the shape directly designed on the machine corresponds exactly to what appears on the simulation screen and to the shape obtained from the machine

» A non-slip program manages at every moment the bar feeding during the bending. In case of slipping, the control adapts the roll feeding to the advancement state of the other axis so to avoid bending errors.

» The CAD-CAM program allows the operator to draw the desired work piece by using the mouse directly on the monitor of the machine; moreover the shape created can also be modified, lengthened and loaded with little operations. If the operator prefers to use another CAD program, the machine can import DXF files and transform them directly into the bending programs

Increased flexibility:

» Programming

» Graphical Design

» Standard Icons

» Graphic view of programmed piece

» X-Y-Z

» DXF

» Multiple Axis Interpolation

»Anti-Slip Automatic Material Feed Tracking System

» Profiling – Spring Back

» Capability of changing a radius during automatic cycle

» Automatic Calibration of Roll Diameters

» Variable Speed Controls

» Networking (optional)

Transition segment lengths (shown above) are automatically maintained throughout the entire bending shape.

CNC-i Bending Examples Using Multiple Axis Interpolation (Shown Below)

Programming Input Options:

CAD/CAM - Graphical Design: Use simple data entry to draw the piece and watch as the program is automatically created.

Interacting Icons - Click on a standard shape and you will be prompted thru the simple design process .

X-Y-Z Table - Manually enter data directly into programming table.

DXF - Load a DXF file to the machine from a USB Memory Stick or download from network. The Control the DXF can be automatically converted to machine program.

Possibility of correcting a radius while the machine is running in automatic- This is a great feature when setting up to avoid scrap.

Variable Speed Controls: Increase or decrease speed while the piece is being bent without affecting the programmed shape.