Image 1 of 33

Image 1 of 33

Image 2 of 33

Image 2 of 33

Image 3 of 33

Image 3 of 33

Image 4 of 33

Image 4 of 33

Image 5 of 33

Image 5 of 33

Image 6 of 33

Image 6 of 33

Image 7 of 33

Image 7 of 33

Image 8 of 33

Image 8 of 33

Image 9 of 33

Image 9 of 33

Image 10 of 33

Image 10 of 33

Image 11 of 33

Image 11 of 33

Image 12 of 33

Image 12 of 33

Image 13 of 33

Image 13 of 33

Image 14 of 33

Image 14 of 33

Image 15 of 33

Image 15 of 33

Image 16 of 33

Image 16 of 33

Image 17 of 33

Image 17 of 33

Image 18 of 33

Image 18 of 33

Image 19 of 33

Image 19 of 33

Image 20 of 33

Image 20 of 33

Image 21 of 33

Image 21 of 33

Image 22 of 33

Image 22 of 33

Image 23 of 33

Image 23 of 33

Image 24 of 33

Image 24 of 33

Image 25 of 33

Image 25 of 33

Image 26 of 33

Image 26 of 33

Image 27 of 33

Image 27 of 33

Image 28 of 33

Image 28 of 33

Image 29 of 33

Image 29 of 33

Image 30 of 33

Image 30 of 33

Image 31 of 33

Image 31 of 33

Image 32 of 33

Image 32 of 33

Image 33 of 33

Image 33 of 33

NTA 370: 14.50" Fully-Automatic, Double-Column Cold Saw

INCLUDES VARIABLE SPEED INVERTER AND 1 BLADE

READY TO PLACE AN ORDER, OR DO YOU HAVE ANY QUESTIONS?

CALL US AT (704) 703-9400

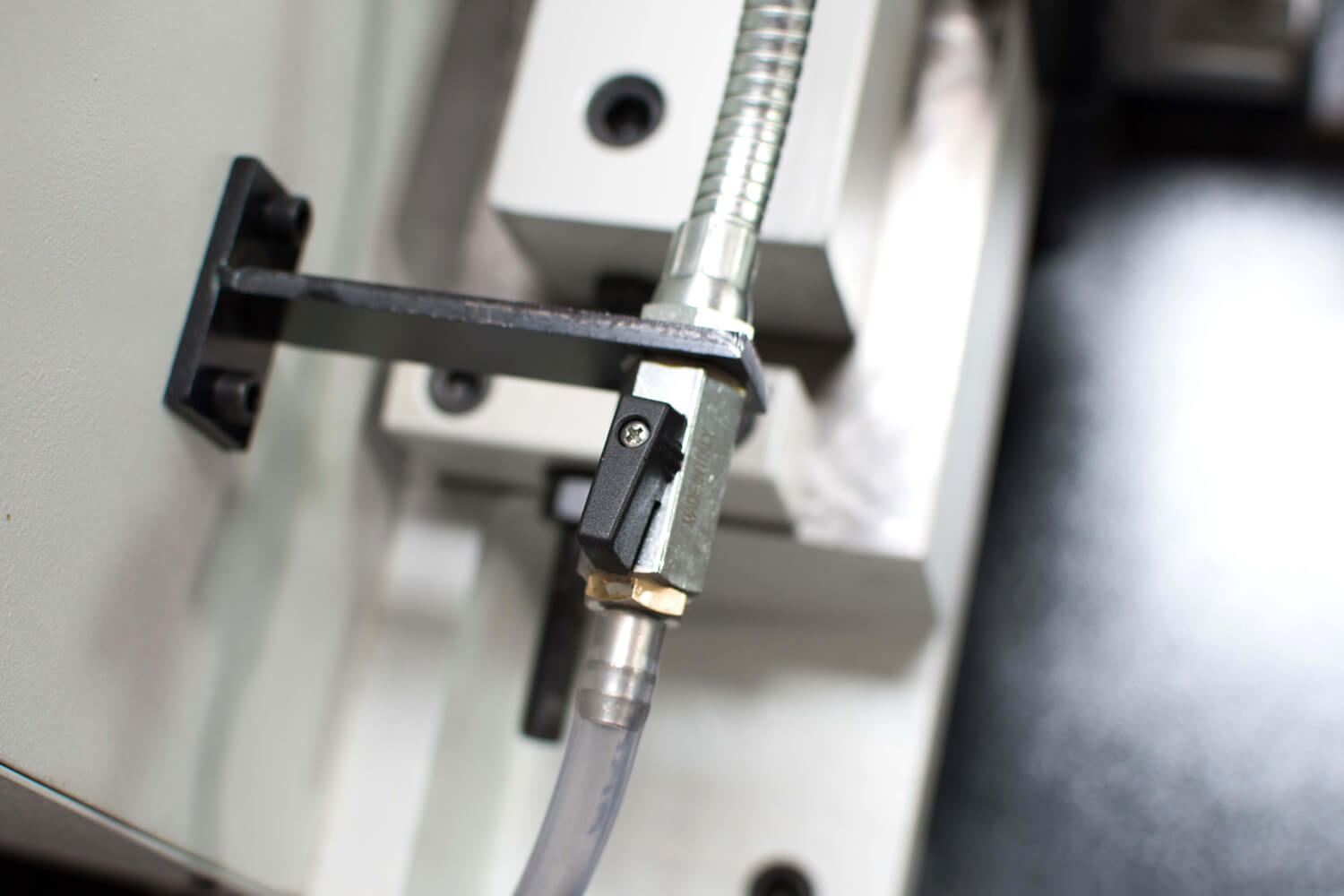

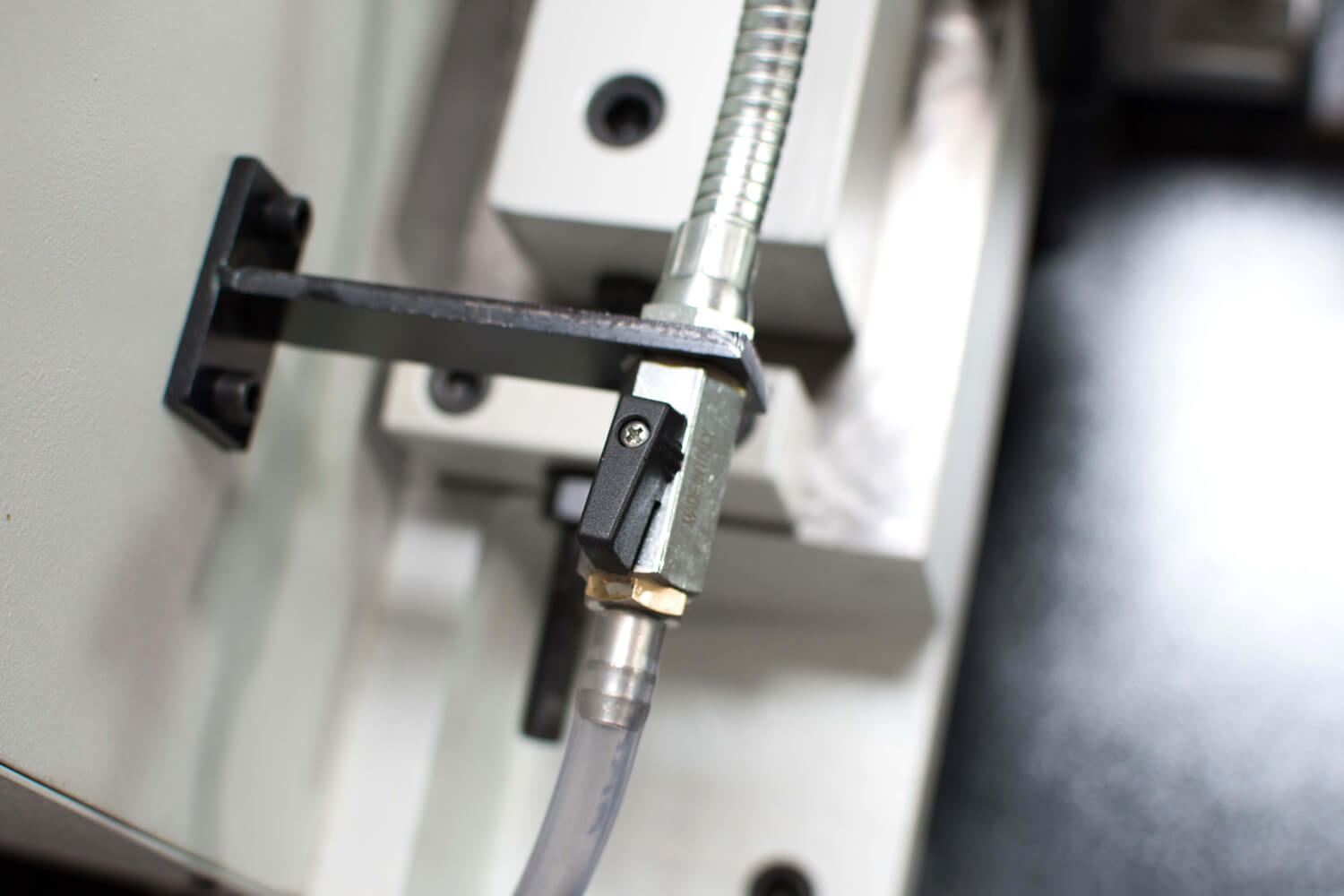

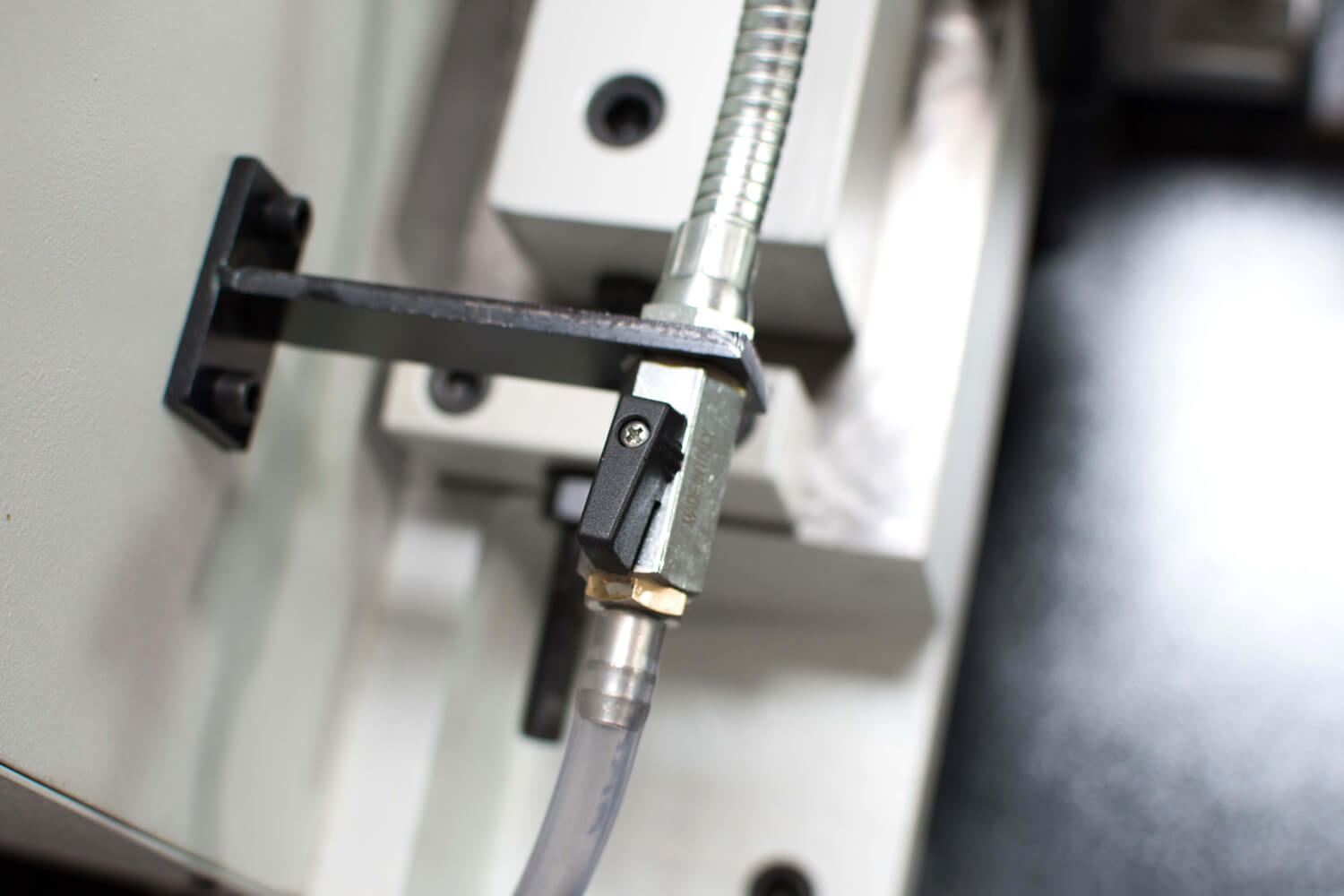

The Quantum Macc NTA 370 Vertical Double-Column Fully-Automatic Cold Saw has a moveable head that can move up to 45 degrees right and left; and the head also has rotation stops at 45° - 0° - 45°. The NTA 370 has a vice that is complete with an anti-burr device, and a motor pump for blade lubrication. This unit is equipped with a bar stop, bar support arm, and service tools, as well as the machine's manual. The NTA 370 can store up to 9 programs, each of them with 99 steps for a total of about 890 cutting positions with relevant piece-counter.

INCLUDES VARIABLE SPEED INVERTER AND 1 BLADE

READY TO PLACE AN ORDER, OR DO YOU HAVE ANY QUESTIONS?

CALL US AT (704) 703-9400

The Quantum Macc NTA 370 Vertical Double-Column Fully-Automatic Cold Saw has a moveable head that can move up to 45 degrees right and left; and the head also has rotation stops at 45° - 0° - 45°. The NTA 370 has a vice that is complete with an anti-burr device, and a motor pump for blade lubrication. This unit is equipped with a bar stop, bar support arm, and service tools, as well as the machine's manual. The NTA 370 can store up to 9 programs, each of them with 99 steps for a total of about 890 cutting positions with relevant piece-counter.

INCLUDES VARIABLE SPEED INVERTER AND 1 BLADE

READY TO PLACE AN ORDER, OR DO YOU HAVE ANY QUESTIONS?

CALL US AT (704) 703-9400

The Quantum Macc NTA 370 Vertical Double-Column Fully-Automatic Cold Saw has a moveable head that can move up to 45 degrees right and left; and the head also has rotation stops at 45° - 0° - 45°. The NTA 370 has a vice that is complete with an anti-burr device, and a motor pump for blade lubrication. This unit is equipped with a bar stop, bar support arm, and service tools, as well as the machine's manual. The NTA 370 can store up to 9 programs, each of them with 99 steps for a total of about 890 cutting positions with relevant piece-counter.

NTA 370 COLD SAW CUTTING CAPACITIES:

Round Tube Cutting Capacities:

Round Tube Cutting at 90° (Straight Cut): 3"

Round Tube Cutting at 45° Left: 3"

Round Tube Cutting at 45° Right: 3"

Square Tube Cutting Capacities:

Square Tube Cutting at 90° (Straight Cut): 3"

Square Tube Cutting at 45° Left: 3"

Square Tube Cutting at 45° Right: 3"

Solid Round Cutting Capacities:

Solid Round Cutting at 90° (Straight Cut): 3"

Solid Round Cutting at 45° Left: 3"

Solid Round Cutting at 45° Right: 3"

Rectangular Tube Cutting Capacities:

Rectangular Tube Cutting at 90° (Straight Cut): 3-7/8" x 3"

Rectangular Tube Cutting at 45° Left: 3-7/8" x 3"

Rectangular Tube Cutting at 45° Right: 3-7/8" x 3"

NTA 370 COLD SAW SPECIFICATIONS:

— Blade Size Used: 370 x 2.5 x 32mm Bore HSS Blade

— 2 Speeds: 25 & 50 R.P.M.

— Weight: 1,985 lbs. (900 kg.)

— Maximum Vice Opening: 7.2” (185mm)

— Step Feeder Stroke Length: 23.60”

— Overall Dimensions: 138” Width x 48” Length x 75” Height (3500 x 1200 x 1900 mm)

— The NTA 370 can store up to 9 programs, each of them with 99 steps for a total of about 890 cutting positions with relevant piece-counter.

— Tempered and ground vertical slider along with Tempered and ground vice jaws

— Head lowering adjustment.

— Equipped with the Shave breaker and Vice complete with Anti-Burr Device.

Cycle start is obtained by pressing the relevant start pedal. The machine performs the following operations during the cutting cycle:

Feeding of Material.

Closing of Vice and Fixed Vice will Lock.

Activation of Blade Motor, Rotation of the Blade and Delivery of Coolant.

Cutting Head Begins Down-Stroke. (While the head is descending to make the cut, the Feeding Carriage will return to the fixed measure - preparing itself for the next step of feeding the material).

Completes Cut & Head Returns to Initial Position as Blade Motor and Coolant Stops.

The Vice will then Open (if there is another step, the step feeder will then begin to feed).

(REPEAT)